Automated Pattern & Process Metrology

ProSEM is an advanced SEM metrology and automation package for monitoring of micro and nanostructures, process calibration and lithographic patterns.

Lithography tools (electron or laser beam and optical) combined with additional data preparation and process improvement techniques are highly optimized and automated for the patterning of micro and nanostructures.

However, SEM based metrology and process monitoring are manual and tedious to perform. Nowadays R&D institutions, multi-user facilities, and specialized small-batch manufacturing companies call for easy, automated, and reliable measurements – which ProSEM does provide.

“Pro” Your SEM!

VERSATILE

- Easy and optimized for micro and nanofabrication

- Layout design and application flexibility

ProSEM is designed for simplicity with a clean user interface and project handling. Both loading images fully calibrated and exporting results is done easily. While all methods are optimized for SEM imaging and classical CMOS structures can be measured, ProSEM also supports various features and element types used in R&D nanofabrication.

CONSISTENT

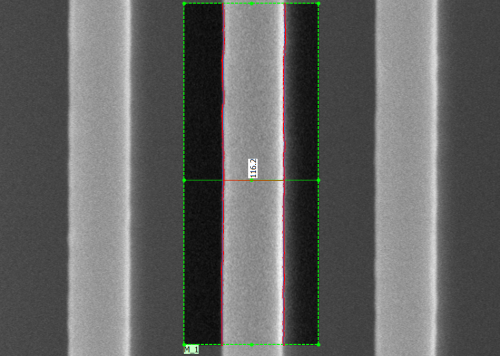

- Precise and calibrated SEM image analysis

- Repeatable results and large data sets

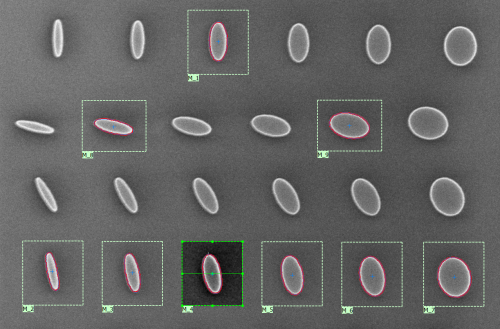

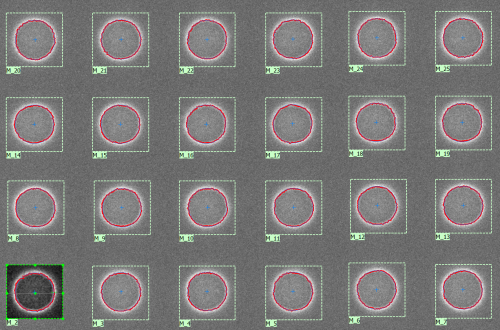

ProSEM is based on sophisticated algorithms for automatic edge detection and feature fitting. This enables multiple measurements and statistical data sets for reliable results, which can be visualized and summarized in data tables. Moreover, ProSEM provides analysis like LER and PSD or more advanced contour measurement and extraction.

PRODUCTIVE

- Automated image acquisition and processing

- Layout-based metrology and batch recipes

ProSEM is very powerful in measuring similar features and pattern arrays automatically. With defining metrology recipes, the batch mode operation can be applied to large image sets and different projects. Additional capabilities of ProSEM include layout-based measurement definition and automated SEM image acquisition via a digital interface.

New Features in Latest Versions

General Metrology Features